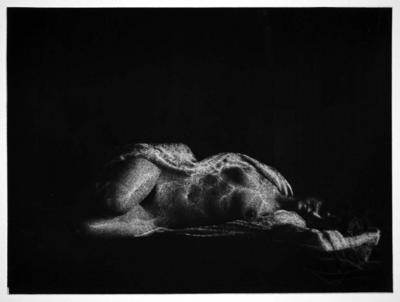

click image to pop-up enlargement

The copper plate for this mezzotint was entirely produced by CNC machine holding two conventional EC Lyons tools -- a diamond-tipped dry-point graver which was used to scribe a series of parallel lines at 50 lines per inch over the entire plate, then another set of lines at a 15 degree angle to the first set, and so on through 180 degrees.

Then a small ball-end burnisher was used to burnish out the highlights in about 13 steps...

First the machine followed the contour of all non-black areas, then all but the two darkest areas, then all but the three darkest areas, and so on until the final pass burnished only the lightest areas.

The plate was then inked, wiped, and printed as usual with intaglios.

This allows the shafts to be removed without totally loosening the mounts.cnc machine

ReplyDelete